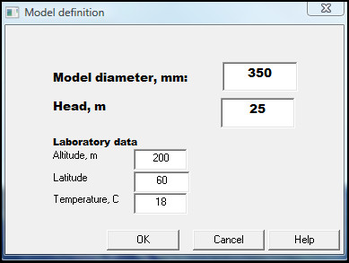

Selecting <Model> on the <Turbine designer> menu opens a dialog box for setting of model- and laboratory data. Alab creates a model according to these data including model roughness data. Drafts and data on <Workbench> get model references and actual report modules will be available. Alab stores data as prototype data. Modification of model design is prohibited. Closing program will automatically reset prototype.

To make and test a model may be an art of balancing on an edge, even if IEC-standards give instructions for model design and testing routines. For practical reasons a model is normally not 100% homologue. Relative roughness may be very different from prototype. This will influence flow in narrow clearances, resulting in extra friction losses in labyrinth sealing. On the other hand deformation of head cover and stay vanes will be small because model testing takes place at heads lower than normal operating head for the prototype. This gives reduced leakage losses under and over the guide vanes. Even simulation of deformation by increasing clearances artificially may give doubtful information due to the roughness problem. The effect will also be different for high head and low head turbines.

A model with high efficiency is a good basis for a good prototype. But as the losses depend on deformation and relative roughness some of the prototype losses will not be fairly treated in the model. Good understanding of the parameters influencing losses is there for necessary to make a prototype that takes all benefit from the model

Efficiency scaling is connected to an anticipated relation between friction- and whirl losses. The relation depends of turbine type. But even turbines with same specific speed will have different loss distribution. A prototype based on a model with low efficiency due to attack losses will according to normal scaling procedures get too high efficiency.

Principally Pelton geometrical dimensions shall be small compared with head, ref. Froude number. A homologue Pelton model tested with higher Froude number than the prototype will give unreliable results. The reason may be that screens and baffles with the intention to control flow of water in the casing and leading water away from runner becomes inactive due to low discharge energy compared with casing dimensions.